- Home

-

Machines

- Horizontal Lathe

- CNC Flat Bed Lathe

- CNC Slant Bed Lathe

- Vertical Lathe

- Pipe Threading Lathe

- See All Lathe

- Vertical Machining Center

- Milling and Boring Machine

- Conventional Milling Machine

- Drilling and Milling Machine

- See All Milling Machine

- Magnetic Drilling Machine

- Belt-driven Drilling Machine

- Gear-driven Drilling Machine

- Radial Drilling Machine

- See All Drilling Machine

- Belt Disc Grinder

- Bench Grinder

- Tool Grinder

- Surface Grinding Machine

- Cylindrical Grinding Machine

- See All Grinding Machine

-

Accessories

- Tool Holder

- Drill Chuck

- Lathe Center

- Lathe Chuck

- Lathe Toolpost Grinder

- Quick Change Tool Post

- Clamping Kit

- Parallel Tool

- Power Feed

- Dividing Head

- Rotary Table

- Work Table

- Machine Vise

- Slotting Head

- Machine Mount

- Magnetic Tool

- Work Lamp

- Digital Readout

- Coolant and Lubrication

- See All Machine Accessory

- Resources

- Our Company

- Contact Us

- Current location:

- Home

- Machines

- Metal Forming Machine

- Press Brake

- WE67K

WE67K

Electro-hydraulic Synchronous CNC Bending Machine

Combined structure.

Stand configuration with 3+1 axes: Y1 (upward-downward of left cylinder), Y2 (upward-downward of right cylinder), X (forward-backward of backgauge), V (hydraulic crowning).

DELEM DA52 for standard configuration, DA56, DA65W for option.

Mechanical or hydraulic crowning mechanism, horizontal compensation is automatically controlled by the CNC system.

Main hydraulic and electric parts are from international famous brands.

A set of standard tools is provided with each machine, special tools are available according to customer's requirements.

Model | Bending Force | Bending Length | Column Distance | Throat Depth | Cylinder Stroke | Open Height | Approaching Speed | Ram Speed | Return Speed | Motor Power | Dimensions | Machine Weight |

Unit | kN | mm | mm | mm | mm | mm | mm/s | mm/s | mm/s | kW | mm | kg |

WE67K-63/2500 | 630 | 2500 | 2050 | 250 | 150 | 330 | 100 | 8 | 100 | 5.5 | 2750x1400x2180 | 5100 |

WE67K-100/2500 | 1000 | 2500 | 2050 | 320 | 150 | 420 | 100 | 10 | 70 | 7.5 | 2750x1600x2450 | 6200 |

WE67K-100/3200 | 1000 | 3200 | 2600 | 320 | 150 | 420 | 100 | 10 | 70 | 7.5 | 3450x1600x2450 | 7650 |

WE67K-100/4000 | 1000 | 4000 | 3200 | 320 | 150 | 420 | 100 | 10 | 70 | 7.5 | 4250x1800x2720 | 8900 |

WE67K-125/3200 | 1250 | 3200 | 2600 | 320 | 150 | 420 | 100 | 8 | 70 | 7.5 | 3450x1600x2450 | 8100 |

WE67K-125/4000 | 1250 | 4000 | 3200 | 320 | 150 | 420 | 100 | 8 | 70 | 7.5 | 4250x1800x2720 | 9450 |

WE67K-160/3200 | 1600 | 3200 | 2600 | 320 | 200 | 470 | 140 | 9.5 | 100 | 11 | 3450x2050x2900 | 10700 |

WE67K-160/4000 | 1600 | 4000 | 3200 | 320 | 200 | 470 | 140 | 9.5 | 100 | 11 | 4250x2050x2900 | 13000 |

WE67K-200/3200 | 2000 | 3200 | 2600 | 320 | 220 | 510 | 140 | 10 | 110 | 15 | 3450x2000x2900 | 12700 |

WE67K-200/4000 | 2000 | 4000 | 3200 | 320 | 220 | 510 | 140 | 10 | 110 | 15 | 4250x2000x3100 | 15100 |

WE67K-200/5000 | 2000 | 5000 | 4000 | 320 | 220 | 510 | 140 | 10 | 110 | 15 | 5250x2100x3200 | 17500 |

WE67K-200/6000 | 2000 | 6000 | 4800 | 320 | 220 | 510 | 140 | 10 | 110 | 15 | 6250x2100x3200 | 18500 |

WE67K-250/3200 | 2500 | 3200 | 2600 | 400 | 240 | 530 | 140 | 8 | 100 | 18.5 | 3450x2000x2900 | 16000 |

WE67K-250/4000 | 2500 | 4000 | 3200 | 400 | 240 | 530 | 140 | 8 | 100 | 18.5 | 4250x2000x3000 | 18000 |

WE67K-250/5000 | 2500 | 5000 | 4000 | 400 | 240 | 530 | 140 | 8 | 100 | 18.5 | 5250x2100x3200 | 21000 |

WE67K-250/6000 | 2500 | 6000 | 4800 | 400 | 240 | 530 | 140 | 8 | 100 | 18.5 | 6250x2100x3200 | 23000 |

WE67K-300/3200 | 3000 | 3200 | 2600 | 400 | 240 | 560 | 140 | 8 | 110 | 22 | 3450x2280x3200 | 19300 |

WE67K-300/4000 | 3000 | 4000 | 3200 | 400 | 240 | 560 | 140 | 8 | 110 | 22 | 4250x2380x3300 | 22000 |

WE67K-300/6000 | 3000 | 6000 | 4800 | 400 | 240 | 560 | 140 | 8 | 110 | 22 | 6250x2380x3500 | 29300 |

WE67K-400/4000 | 4000 | 4000 | 3200 | 400 | 240 | 560 | 80 | 8 | 60 | 30 | 4250x2350x3595 | 30000 |

WE67K-400/6000 | 4000 | 6000 | 4800 | 400 | 240 | 560 | 80 | 8 | 60 | 30 | 6250x2350x3595 | 35000 |

1. Machine model and name | |||

1.1 Name: CNC bending machine | |||

2. The accuracy of the CNC axis of the machine | |||

CNC axis | Repeat accuracy | Control precision | |

Y axis (Y1/Y2) | 0.01mm | 0.02mm | |

X axis | 0.02mm | 0.05mm | |

3. Product standard | |||

Q/HSD 76706-2006 "Accuracy of CNC Sheet Metal Bending Machine" | |||

4. The overall performance of the machine | |||

4.1 Structural steel plate welded structure, strong rigidity. | |||

4.2 Structural parts are derusted by sanding and sprayed with anti-rust paint. | |||

4.3 The column, upper working slide block, and lower working table of the machine tool adopt a large floor boring and milling machine, and use the integral one-time processing method for precision processing to ensure the overall processing accuracy of the machine tool. | |||

4.4 Upward bending design, stable work, convenient operation and safe. | |||

4.5 There is a pressure-holding delay function at the bottom dead center to ensure the accuracy of the workpiece. | |||

4.6 The slider has a large stroke and a high tolerance for parallelism on both sides. | |||

4.7 Under the relevant national standard conditions, the bending angle accuracy can reach ±30'. | |||

4.8 With the function of slow descent control, the operator can better control the workpiece. | |||

4.9 Workbench deflection compensation function ensures bending accuracy. | |||

4.10 The stopper is driven and controlled by a servo motor, which has fast speed, stable transmission, high precision and low noise. | |||

5. Hydraulic system | |||

| |||

5.1 Adopt the special synchronous control system of German Rexroth's bending machine, which can obtain higher synchronous control accuracy. The hydraulic system has overload and overflow protection, which is safe and reliable. | |||

5.2 The gear pump used for the oil pump can withstand high pressure and has low noise. | |||

5.3 Cylinder: 45# steel quenching and tempering treatment, inner hole fine boring and grinding. | |||

5.4 Piston: 45# steel quenching and tempering treatment, external high frequency quenching or chrome plating, fine grinding, vibration grinding (super fine grinding). | |||

5.5 The sealing ring is selected from Japan's NOK company, which has good sealing performance, reliable work and long life. | |||

5.6 There is a clear and intuitive display of oil level and temperature. | |||

5.7 The hydraulic system is divided into coarse and fine two-stage filtration, with high filtration accuracy. | |||

6. Electrical control system | |||

6.1 The key electrical components are imported from abroad, which conform to international standards, are safe and reliable, have a long life, and have strong anti-interference ability. The electric control cabinet has a heat dissipation function. | |||

6.2 Movable foot switch operation, with emergency power off function. | |||

7. The function of CNC axis | |||

| |||

7.1 The Y1 and Y2 axes are the slider stroke control axes, which are used to control the bending angle. | |||

Two grating rulers (Y1-Y2) are installed at both ends of the machine tool. They are used to determine the exact position of the slider and the worktable; the grating ruler is connected to the worktable so that the deformation of the column will not affect the positioning of the slider. The position data is immediately fed back to the numerical control system, and it can measure and output the servo valve control signal. | |||

7.2 V axis adopts convex control axis (that is, deflection compensation). | |||

Using LVD's unique embossing worktable design and manufacturing technology, a family of ideal embossing curves can be formed, and compensation is achieved over the full length to offset the deformation of the slider and the worktable under stress, and improve the quality of the parts. | |||

7.3 X axis is the backgauge control axis, used to control the flange size of the bending machine. | |||

The X axis uses an imported servo motor to drive the ball screw through a synchronous toothed belt wheel. The two stop jaws are always synchronized during the movement. Smooth transmission, high precision and low noise. | |||

8. Mould | |||

| |||

A set of standard upper and lower molds | |||

Standard fixture: Quick clamp | |||

9. Anti-eccentric load capacity of the machine | |||

The power supply servo system of this machine is a position control system. It dynamically detects the synchronization error of the slider through the grating ruler. The electro-hydraulic servo valve signal is given by the numerical control system to correct the synchronization error of the slider, so that the slider is completely deviated. It can always be parallel to the workbench under load. | |||

10. CNC system | |||

◇DA-52S numerical control system of Dutch DELEM company (standard configuration) | |||

| |||

·One-page parameter quick programming | |||

·Navigation shortcut keys | |||

·7" widescreen color TFT | |||

·Max four-axis control (Y1Y2 and two additional axes) | |||

·Workbench deflection compensation control | |||

·USB peripheral interface | |||

·Advanced Y-axis control algorithm, which can control both closed-loop and open-loop valves | |||

·Panel type installation structure, optional hanging box | |||

◇DA58T/DA66T/DA69T CNC system (optional) of Dutch DELEM company | |||

|  |  | |

11. Key imported parts | |||

◇Numerical control system DELEM, the Netherlands | |||

◇Module DELEM, the Netherlands | |||

◇Servo valve group Rexroth, Germany | |||

◇Pressure valve group Rexroth, Germany | |||

◇Grating ruler HEIDENHAIN AG, Germany | |||

◇ Rod seals NOK company in Japan | |||

◇ Sealed ring NOK company in Japan | |||

◇Cylinder sealing ring NOK company in Japan | |||

◇Dustproof ring NOK company in Japan | |||

◇Direction belt NOK company in Japan | |||

◇Servo motor Estun | |||

◇Servo drive Estun | |||

12. Other standard configuration of machine | |||

◇Ball screw for X-axis drive | |||

◇4 backgauge stop claws | |||

◇1 set of foot switch | |||

◇4 anchor bolts | |||

◇4 pads | |||

◇1 set of instructions for use | |||

Recommended Products

-

VMC850P

VMC850PTravel X/Y/Z axis 850/500/550mm

Worktable size 1000x500mm

¥0.00 ¥0.00VIP : ¥ -

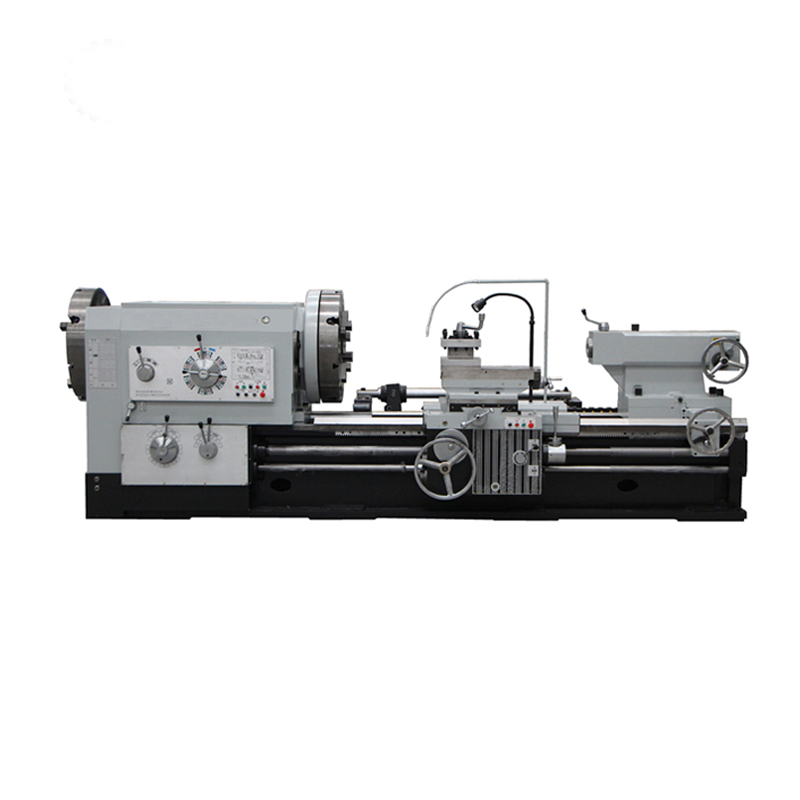

CY6250B,CY6266B

CY6250B,CY6266BSwing over bed 500/660mm

Workpiece length 3000mm

Spindle bore 82mm

Spindle speed 9-1600rpm

¥0.00 ¥0.00VIP : ¥ -

C6241,C6246

C6241,C6246Swing over bed 410/460mm

Workpiece length 1000/1500mm

Spindle bore 58/82mm

Spindle speed 25-2000rpm

¥0.00 ¥0.00VIP : ¥ -

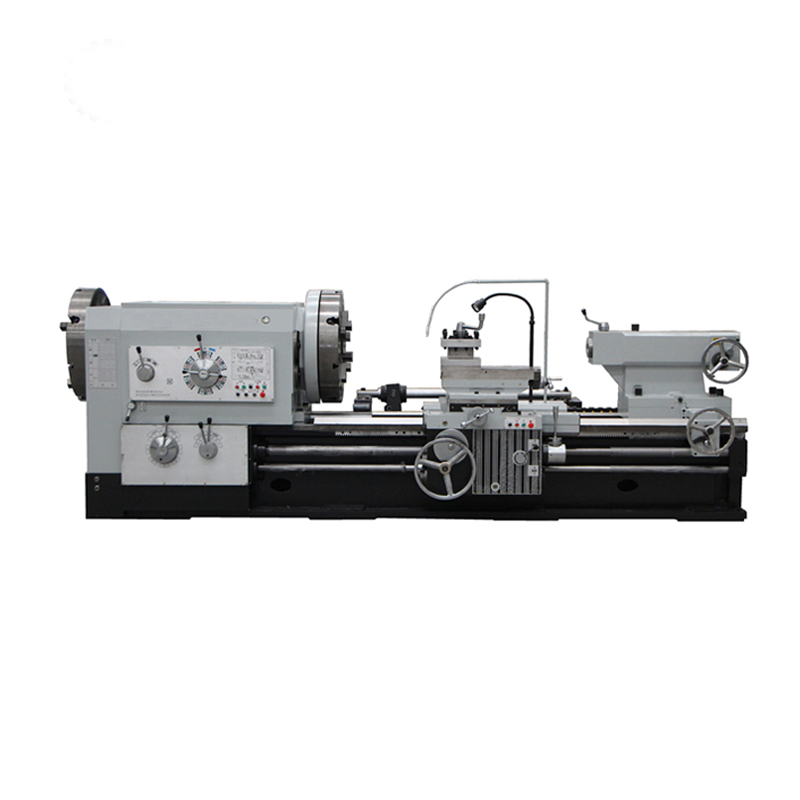

C6251,C6256

C6251,C6256Swing over bed 510/560mm

Workpiece length 3000mm

Spindle bore 80/105mm

Spindle speed 25-2000rpm

¥0.00 ¥0.00VIP : ¥ -

NB

NB4Pcs

¥0.00 ¥0.00VIP : ¥ -

Broach Set

Broach SetMetric & Inch

¥0.00 ¥0.00VIP : ¥ -

TG Nut

TG NutTG75/100/150

¥0.00 ¥0.00VIP : ¥ -

LDB Live Center

LDB Live CenterMT3-6

Max. speed 4000rpm

¥0.00 ¥0.00VIP : ¥ -

SER

SER1Pc

¥0.00 ¥0.00VIP : ¥ -

ZT-100F-A,ZT-100F-B

ZT-100F-A,ZT-100F-BThreading capacity 1/2"-4"

Power 1500W

Speed 12/22/38rpm

¥0.00 ¥0.00VIP : ¥ -

ZT-50AF

ZT-50AFThreading capacity 1/2"-2"

Power 1100W

Speed 30rpm

¥0.00 ¥0.00VIP : ¥ -

Q1313,Q1319C,Q1322C

Q1313,Q1319C,Q1322CSwing over bed 630-800mm

Spindle bore 130-225mm

¥0.00 ¥0.00VIP : ¥ -

CK6140ZX,CK6146ZX,CK6150ZX

CK6140ZX,CK6146ZX,CK6150ZXSwing over bed 400-500mm

Workpiece length 1500mm

¥0.00 ¥0.00VIP : ¥ -

CD6240B,CD6250B,CD6260B,CD6266B

CD6240B,CD6250B,CD6260B,CD6266BSwing over bed 410-660mm

Workpiece length 3000mm

Spindle bore 65mm

Spindle speed 22-1800rpm

¥0.00 ¥0.00VIP : ¥ -

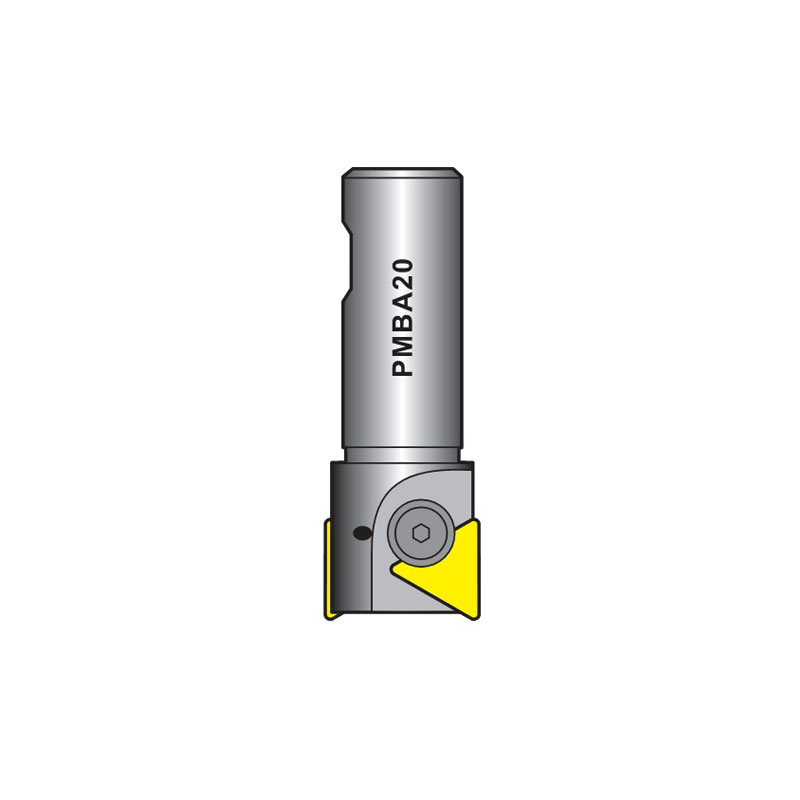

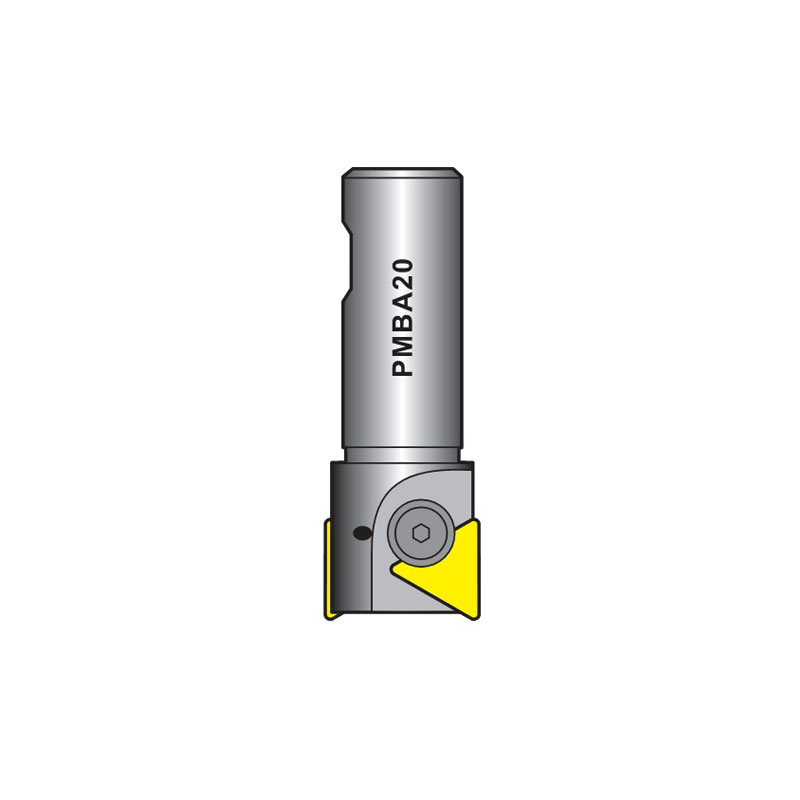

PMBA

PMBACutter dia. 12-50mm

¥0.00 ¥0.00VIP : ¥

What product are you looking for?

Feel free to check our products, it would be our pleasure if some of them happen to be just as you want them to be.

Here We Are

Qingzhou Shengmao Machinery Co., Ltd.

South Hedong Village,

Yidu Subdistrict, Qingzhou City, Shandong Province, China 262500

© 2024 Qingzhou Shengmao Machinery Co., Ltd. All rights reserved