- Home

-

Machines

- Horizontal Lathe

- CNC Flat Bed Lathe

- CNC Slant Bed Lathe

- Vertical Lathe

- Pipe Threading Lathe

- See All Lathe

- Vertical Machining Center

- Milling and Boring Machine

- Conventional Milling Machine

- Drilling and Milling Machine

- See All Milling Machine

- Magnetic Drilling Machine

- Belt-driven Drilling Machine

- Gear-driven Drilling Machine

- Radial Drilling Machine

- See All Drilling Machine

- Belt Disc Grinder

- Bench Grinder

- Tool Grinder

- Surface Grinding Machine

- Cylindrical Grinding Machine

- See All Grinding Machine

-

Accessories

- Tool Holder

- Drill Chuck

- Lathe Center

- Lathe Chuck

- Lathe Toolpost Grinder

- Quick Change Tool Post

- Clamping Kit

- Parallel Tool

- Power Feed

- Dividing Head

- Rotary Table

- Work Table

- Machine Vise

- Slotting Head

- Machine Mount

- Magnetic Tool

- Work Lamp

- Digital Readout

- Coolant and Lubrication

- See All Machine Accessory

- Resources

- Our Company

- Contact Us

- Current location:

- Home

- Machines

- Metal Forming Machine

- Press Brake

- WC67E

WC67E

Electro-hydro CNC Press Brake

CNC press brake has better bending accuracy and higher bending efficiency, and the bending times are increased by at least 30% in the same bending time.

Controller Brand: DELEM, CYBELEC, ESA

| ||||||||||||

Model | Bending Force | Bending Length | Approaching Speed | Ram Speed | Return Speed | Column Distance | Throat Depth | Stroke | Open Height | Step/Servo Motor | Weight | Dimensions |

(A) | (B) | (D) | (C) | (E) | ||||||||

Unit | kN | mm | mm/s | mm/s | mm/s | mm | mm | mm | mm | kW | t | L*W*H mm |

WC67E-30T/1600 | 300 | 1600 | 120 | 17 | 160 | 1300 | 200 | 80 | 320 | 5.5 | 2.3 | 1650*1200*1700 |

WC67E-30T/2000 | 300 | 2000 | 140 | 17 | 160 | 1300 | 200 | 80 | 320 | 5.5 | 2.5 | 2000*1200*1700 |

WC67E-40T/2500 | 400 | 2500 | 110 | 15 | 90 | 2030 | 250 | 100 | 340 | 5.5 | 3.5 | 2500*1200*1900 |

WC67E-63T/2500 | 630 | 2500 | 100 | 10 | 70 | 2050 | 250 | 120 | 340 | 5.5 | 4.5 | 2500*1350*2100 |

WC67E-63T/3200 | 630 | 3200 | 120 | 10 | 70 | 2510 | 250 | 120 | 340 | 5.5 | 5 | 3200*1350*2100 |

WC67E-80T/2500 | 800 | 2500 | 110 | 10 | 80 | 2050 | 250 | 120 | 350 | 5.5 | 6 | 2500*1400*2150 |

WC67E-80T/3200 | 800 | 3200 | 130 | 10 | 80 | 2510 | 250 | 120 | 350 | 5.5 | 6.2 | 3200*1400*2150 |

WC67E-100T/2500 | 1000 | 2500 | 90 | 8 | 70 | 2050 | 320 | 120 | 380 | 7.5 | 6.5 | 2500*1500*2200 |

WC67E-100T/3200 | 1000 | 3200 | 100 | 8 | 70 | 2510 | 320 | 120 | 380 | 7.5 | 7 | 3200*1500*2300 |

WC67E-100T/4000 | 1000 | 4000 | 120 | 8 | 70 | 3100 | 320 | 120 | 380 | 7.5 | 8.5 | 4000*1500*2400 |

WX67Y-100T/4000 | 1000 | 4000 | 130 | 8 | 70 | 3100 | 420 | 160 | 435 | 7.5 | 9 | 4000*1650*2500 |

WC67E-125T/3200 | 1250 | 3200 | 95 | 7 | 65 | 2510 | 320 | 120 | 380 | 7.5 | 7.5 | 3200*1600*2350 |

WC67E-125T/4000 | 1250 | 4000 | 110 | 7 | 65 | 3100 | 400 | 120 | 380 | 7.5 | 9.5 | 4000*1600*2450 |

WX67Y-125T/4000 | 1250 | 4000 | 120 | 7 | 65 | 3100 | 420 | 160 | 435 | 7.5 | 10 | 4000*1700*2500 |

WC67E-160T/2500 | 1600 | 2500 | 100 | 10 | 100 | 2050 | 320 | 200 | 450 | 11 | 9 | 2500*1650*2700 |

WC67E-160T/3200 | 1600 | 3200 | 110 | 10 | 100 | 2510 | 320 | 200 | 450 | 11 | 11 | 3200*1650*2800 |

WC67E-160T/4000 | 1600 | 4000 | 120 | 10 | 100 | 3040 | 320 | 200 | 450 | 11 | 12 | 4000*1650*2800 |

WC67E-160T/5000 | 1600 | 5000 | 130 | 10 | 100 | 3800 | 320 | 200 | 450 | 11 | 14.5 | 5000*1750*3100 |

WC67E-160T/6000 | 1600 | 6000 | 140 | 10 | 100 | 4600 | 320 | 200 | 450 | 11 | 19.5 | 6000*1750*3300 |

WC67E-200T/3200 | 2000 | 3200 | 80 | 9 | 105 | 2600 | 320 | 250 | 540 | 15 | 13.5 | 3200*1900*3100 |

WC67E-200T/3200C | 2000 | 3200 | 110 | 10 | 100 | 2510 | 320 | 200 | 450 | 11 | 11.5 | 3200*1650*2800 |

WC67E-200T/4000 | 2000 | 4000 | 90 | 9 | 105 | 3300 | 320 | 250 | 540 | 15 | 15 | 4000*1900*3100 |

WC67E-200T/4000C | 2000 | 4000 | 120 | 10 | 100 | 3040 | 320 | 200 | 450 | 11 | 12.5 | 4000*1650*2800 |

WC67E-200T/5000 | 2000 | 5000 | 120 | 7 | 80 | 3800 | 320 | 250 | 540 | 15 | 19 | 5000*1950*3100 |

WC67E-200T/6000 | 2000 | 6000 | 120 | 7 | 80 | 4600 | 320 | 250 | 540 | 15 | 21 | 6000*1950*3100 |

WC67E-250T/3200 | 2500 | 3200 | 90 | 9 | 100 | 2600 | 400 | 250 | 580 | 18.5 | 17 | 3300*2100*3150 |

WC67E-250T/4000 | 2500 | 4000 | 100 | 9 | 100 | 3300 | 400 | 250 | 580 | 18.5 | 20 | 4000*2100*3150 |

WC67E-250T/5000 | 2500 | 5000 | 110 | 8 | 100 | 3800 | 400 | 250 | 580 | 18.5 | 23 | 5000*2100*3200 |

WC67E-250T/6000 | 2500 | 6000 | 120 | 8 | 100 | 4600 | 400 | 250 | 580 | 18.5 | 25.5 | 6000*2100*3200 |

WC67E-300T/3200 | 3000 | 3200 | 90 | 8 | 75 | 2600 | 400 | 250 | 580 | 18.5 | 21 | 3200*2200*3200 |

WC67E-300T/4000 | 3000 | 4000 | 100 | 8 | 75 | 3300 | 400 | 250 | 580 | 18.5 | 23 | 4000*2200*3200 |

WC67E-300T/5000 | 3000 | 5000 | 110 | 8 | 75 | 3800 | 400 | 250 | 580 | 18.5 | 25 | 5000*2200*3200 |

WC67E-300T/6000 | 3000 | 6000 | 130 | 8 | 75 | 4600 | 400 | 250 | 580 | 18.5 | 27.5 | 6000*2200*3200 |

WC67E-400T/4000 | 4000 | 4000 | 70 | 7 | 60 | 3300 | 400 | 250 | 580 | 22 | 26 | 4000*2400*3200 |

WC67E-400T/5000 | 4000 | 5000 | 80 | 7 | 60 | 3800 | 400 | 250 | 580 | 22 | 32 | 5000*2400*3200 |

WC67E-400T/6000 | 4000 | 6000 | 100 | 7 | 60 | 4400 | 400 | 250 | 580 | 22 | 35 | 6000*2400*3200 |

WC67E-500T/4000 | 5000 | 4000 | 70 | 6 | 55 | 3300 | 500 | 320 | 620 | 30 | 33 | 4000*2650*3200 |

WC67E-500T/5000 | 5000 | 5000 | 90 | 6 | 55 | 3800 | 500 | 320 | 620 | 30 | 37.5 | 5000*2650*3200 |

WC67E-500T/6000 | 5000 | 6000 | 120 | 6 | 55 | 4410 | 500 | 320 | 620 | 30 | 43.5 | 6000*2700*3200 |

WC67E-500T/7000 | 5000 | 7000 | 130 | 6 | 55 | 5400 | 500 | 320 | 620 | 30 | 55 | 7000*2700*3200 |

WC67E-600T/4000 | 6000 | 4000 | 80 | 6 | 65 | 3300 | 500 | 320 | 620 | 37 | 45 | 4000*2700*3200 |

WC67E-600T/5000 | 6000 | 5000 | 90 | 6 | 65 | 3800 | 500 | 320 | 620 | 37 | 48 | 5000*2700*3250 |

WC67E-600T/6000 | 6000 | 6000 | 110 | 6 | 65 | 4600 | 500 | 320 | 620 | 37 | 55 | 6000*2700*3300 |

WC67E-600T/7000 | 6000 | 7000 | 120 | 6 | 65 | 5400 | 500 | 320 | 620 | 37 | 62 | 7000*2900*3500 |

Feature | FIG. |

Outlook |  |

NC Controller |  |

Hydraulic System |  |

Motor |  |

Oil Pump |  |

Backgauge |  |

Electrical Parts |  |

Crowning |  |

Punches & Dies |  |

Torsion-sync Bar |  |

Backgauge Servo Motor |  |

Recommended Products

-

RB13,RB14

RB13,RB14Drilling diameter 13mm

Motor power 300W

Table size 330x190mm

Height 610/668mm

¥0.00 ¥0.00VIP : ¥ -

HQ400/3A,HQ400/3L

HQ400/3A,HQ400/3LSwing over bed 420mm

Workpiece length 400/500mm

Spindle bore 20mm

Drilling dia. 15mm

¥0.00 ¥0.00VIP : ¥ -

JYP250V

JYP250VSwing over bed 250mm

Workpiece length 550/750mm

Spindle bore 26mm

Drilling dia. 16mm

¥0.00 ¥0.00VIP : ¥ -

CD6240B,CD6250B,CD6260B,CD6266B

CD6240B,CD6250B,CD6260B,CD6266BSwing over bed 410-660mm

Workpiece length 3000mm

Spindle bore 65mm

Spindle speed 22-1800rpm

¥0.00 ¥0.00VIP : ¥ -

CJ6250YC,CJ6256YC,CJ6266YC,CJ6280YC

CJ6250YC,CJ6256YC,CJ6266YC,CJ6280YCSwing over bed 500-800mm

Workpiece length 4000mm

Spindle bore 105mm

Spindle speed 36-1600rpm

¥0.00 ¥0.00VIP : ¥ -

T-Slot indexable

T-Slot indexableCutter dia. 25-72mm

¥0.00 ¥0.00VIP : ¥ -

C6266Y

C6266YSwing over bed 660mm

Workpiece length 4000mm

Spindle bore 103mm

Spindle speed 9-1275rpm

¥0.00 ¥0.00VIP : ¥ -

C6240ZK,C6246ZK

C6240ZK,C6246ZKSwing over bed 400/460mm

Workpiece length 1500mm

Spindle bore 52mm

Spindle speed 40-1800pm

¥0.00 ¥0.00VIP : ¥ -

C6280Y,C62100Y

C6280Y,C62100YSwing over bed 800/1000mm

Workpiece length 4000mm

Spindle bore 103mm

Spindle speed 9-1275rpm

¥0.00 ¥0.00VIP : ¥ -

C6240ZX,C6246ZX

C6240ZX,C6246ZXSwing over bed 400/460mm

Workpiece length 2000mm

Spindle bore 80mm

Spindle speed 25-1800pm

¥0.00 ¥0.00VIP : ¥ -

C6140W

C6140WSwing over bed 420mm

Workpiece length 2000mm

Spindle bore 56mm

Spindle speed 9-1600pm

¥0.00 ¥0.00VIP : ¥ -

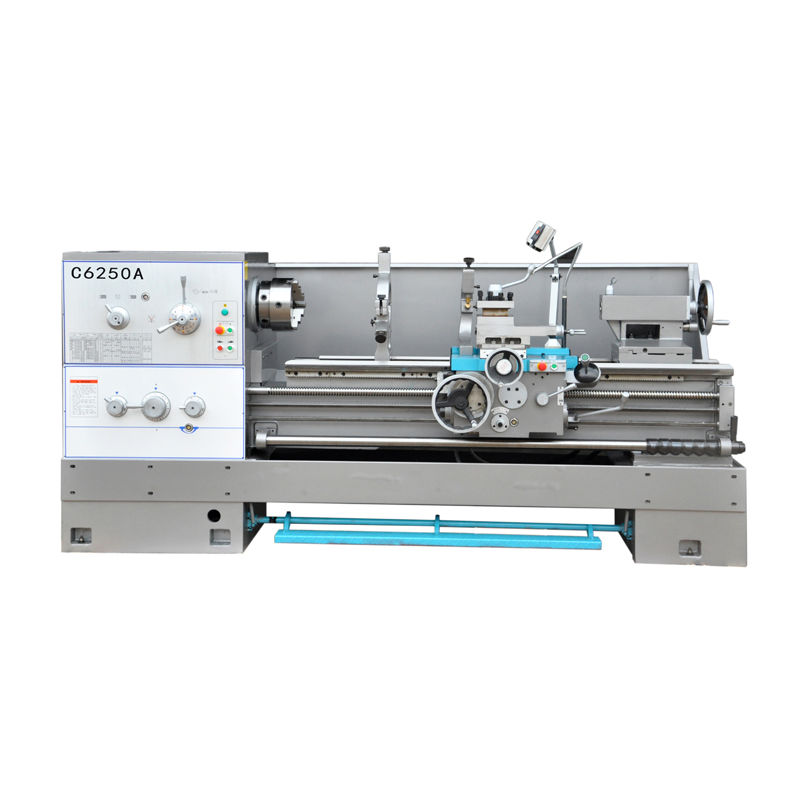

C6250A

C6250ASwing over bed 500mm

Workpiece length 3000mm

Spindle bore 80mm

Spindle speed 36-1600pm

¥0.00 ¥0.00VIP : ¥ -

C6253,C6260,C6266

C6253,C6260,C6266Swing over bed 530-660mm

Workpiece length 1500/2000mm

Spindle bore 82mm

Spindle speed 20-1600rpm

¥0.00 ¥0.00VIP : ¥ -

C6241,C6246

C6241,C6246Swing over bed 410/460mm

Workpiece length 1000/1500mm

Spindle bore 58/82mm

Spindle speed 25-2000rpm

¥0.00 ¥0.00VIP : ¥ -

GH4280,GH42100

GH4280,GH42100Cutting 90° (Round) 800mm

Cutting 90° (Square) 800x800mm

¥0.00 ¥0.00VIP : ¥

What product are you looking for?

Feel free to check our products, it would be our pleasure if some of them happen to be just as you want them to be.

Here We Are

Qingzhou Shengmao Machinery Co., Ltd.

South Hedong Village,

Yidu Subdistrict, Qingzhou City, Shandong Province, China 262500

© 2024 Qingzhou Shengmao Machinery Co., Ltd. All rights reserved