- Home

-

Machines

- Horizontal Lathe

- CNC Flat Bed Lathe

- CNC Slant Bed Lathe

- Vertical Lathe

- Pipe Threading Lathe

- See All Lathe

- Vertical Machining Center

- Milling and Boring Machine

- Conventional Milling Machine

- Drilling and Milling Machine

- See All Milling Machine

- Magnetic Drilling Machine

- Belt-driven Drilling Machine

- Gear-driven Drilling Machine

- Radial Drilling Machine

- See All Drilling Machine

- Belt Disc Grinder

- Bench Grinder

- Tool Grinder

- Surface Grinding Machine

- Cylindrical Grinding Machine

- See All Grinding Machine

-

Accessories

- Tool Holder

- Drill Chuck

- Lathe Center

- Lathe Chuck

- Lathe Toolpost Grinder

- Quick Change Tool Post

- Clamping Kit

- Parallel Tool

- Power Feed

- Dividing Head

- Rotary Table

- Work Table

- Machine Vise

- Slotting Head

- Machine Mount

- Magnetic Tool

- Work Lamp

- Digital Readout

- Coolant and Lubrication

- See All Machine Accessory

- Resources

- Our Company

- Contact Us

- Current location:

- Home

- Machines

- Lathe

- Horizontal Lathe

- CY6250L,CY6266L,CY6276L

CY6250L,CY6266L,CY6276L

The headstock, gear-box, apron and bed-ways are made of high quality cast iron, and are all cast with the resin sand foundry technology and aging process. The bed ways are induction-hardened, with hardness around HRC52.

The spindle supported by 3-pointed high-precision bearings and all gears in headstock are precisely ground, the spindle turns smoothly at high speed.

High rigidity spindle system, with absolute temperature rising no higher than 35°C.

Rapid feed system to improve efficiency. Wide range of feed and pitch are available without changing gears, distance between centers 1000-5000mm, this lathe covers wide range of working pieces.

When rapid feeding is on, the tool slide longitudinal travel handwheel will be automatically nonfunctional.

Reliable safety devices such as footbrake and emergency power-off switch are assembled. Adjustable overload protection device is also installed in the feed system.

The tool post adopts the structure of ratchet pawl, and can be relocked by turning the lever for just half a lap.

Tailstock are equipped with double-locked mechanism, smooth and effortless movement is ensured by the elastic scroll devices underneath.

Specifications | CY6250L | CY6266L | CY6276L |

Swing over bed | 500mm | 660mm | 760mm |

Swing over cross slide | 300mm | 430mm | 530mm |

Distance between centers | 1000/1500/2000/3000mm | ||

Swing in gap | 710mm | 870mm | 970mm |

Width of gap | 240mm | ||

Width of bed | 390mm | ||

Spindle nose | D8 | ||

Spindle bore diameter | 105mm | ||

Taper of spindle center | 1:20 | ||

Spindle speed | 6-1120rpm | ||

Max. output torque of spindle | 1500N.m | ||

Range of longitudinal feed | 0.063-6.43mm/rev | ||

Range of cross feed | 0.027-2.73mm/rev | ||

Lead screw pitch | 12mm (metric system) 2TPI (inch system) | ||

Metric threads | 1-224mm (46 kinds) | ||

Inch threads | 28-1/8TPI (42 kinds) | ||

Module threads | 0.5-112mm (42 kinds) | ||

Diameter pitch threads | 56-1/4DP (45 kinds) | ||

Cross slide travel | 340mm | 360mm | |

Top slide travel | 150mm | 200mm | |

Section specification of tool post | 25x25mm | ||

Longitudinal rapid traveling speed | 4.5m/min (50Hz) / 5.4m/min (60Hz) | ||

Transversal rapid traveling speed | 1.9m/min(50Hz) / 2.3m/min(60Hz) | ||

Morse taper of tailstock center | MT5 | ||

Max. travel of tailstock quill | 150mm | ||

Tailstock quill diameter | 75mm | ||

Main motor | 11kW | ||

Rapid travel motor | 250W 1360rpm | ||

Coolant pump motor | 90W 25L/min | ||

Standard Accessories | Optional Accessories |

3 jaw chuck | Face plate |

Thread chasing dial | 4 jaw chuck |

Chip guard | Steady rest |

Foot brake | Follow rest |

Oil gun | Drive plate |

Live center | Chuck cover |

Dead center | 4 position stop for saddle |

Center sleeve | 4 position stop for cross slide |

Micro stop for saddle | |

Quick change tool post | |

Damping washer | |

Taper turning attachment | |

Halogen work lamp | |

Digital readout (DRO) | |

CE standard compliance |

Recommended Products

-

DDP-0.5,DDP-1,DDP-2,DDP-3

DDP-0.5,DDP-1,DDP-2,DDP-3Pressure force 0.5-3t

¥0.00 ¥0.00VIP : ¥ -

Q1343

Q1343Swing over bed 1000mm

Spindle bore 440mm

¥0.00 ¥0.00VIP : ¥ -

QC12Y

QC12YShear thickness 4-30mm

Shear width 1500-6000mm

¥0.00 ¥0.00VIP : ¥ -

KSE200

KSE200Speed 2950rpm

Motor power 900W

¥0.00 ¥0.00VIP : ¥ -

PS350

PS350Speed 2950rpm

Motor power 900W

¥0.00 ¥0.00VIP : ¥ -

PS200,PS250

PS200,PS250Speed 2950rpm

Motor power 900W

¥0.00 ¥0.00VIP : ¥ -

TX-MD200

TX-MD200Manual chamfer

Bevel angle 15/20/25°

Chamfering range 0-2mm

¥0.00 ¥0.00VIP : ¥ -

3M9735A

3M9735AWorking length 1300-1500mm

Working width 350-400mm

¥0.00 ¥0.00VIP : ¥ -

3M9735B

3M9735BWorking length 1300-1500mm

Working width 350-400mm

¥0.00 ¥0.00VIP : ¥ -

LDB Live Center

LDB Live CenterMT3-6

Max. speed 4000rpm

¥0.00 ¥0.00VIP : ¥ -

Broach Set

Broach SetMetric & Inch

¥0.00 ¥0.00VIP : ¥ -

X715,X716

X715,X716Table size 2100x500/2500x600mm

Travel X axis 1500/1800mm

¥0.00 ¥0.00VIP : ¥ -

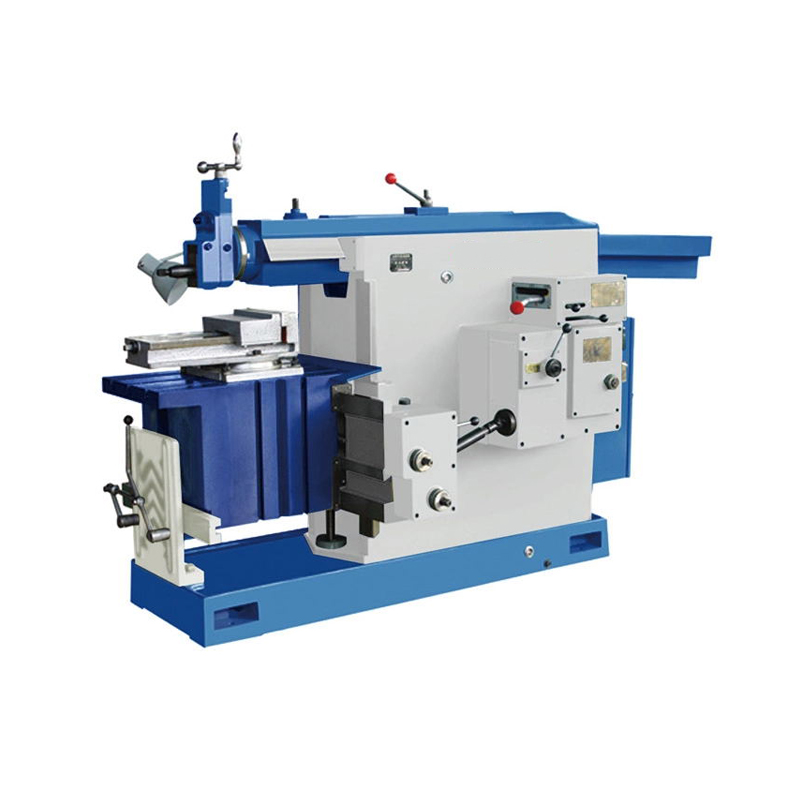

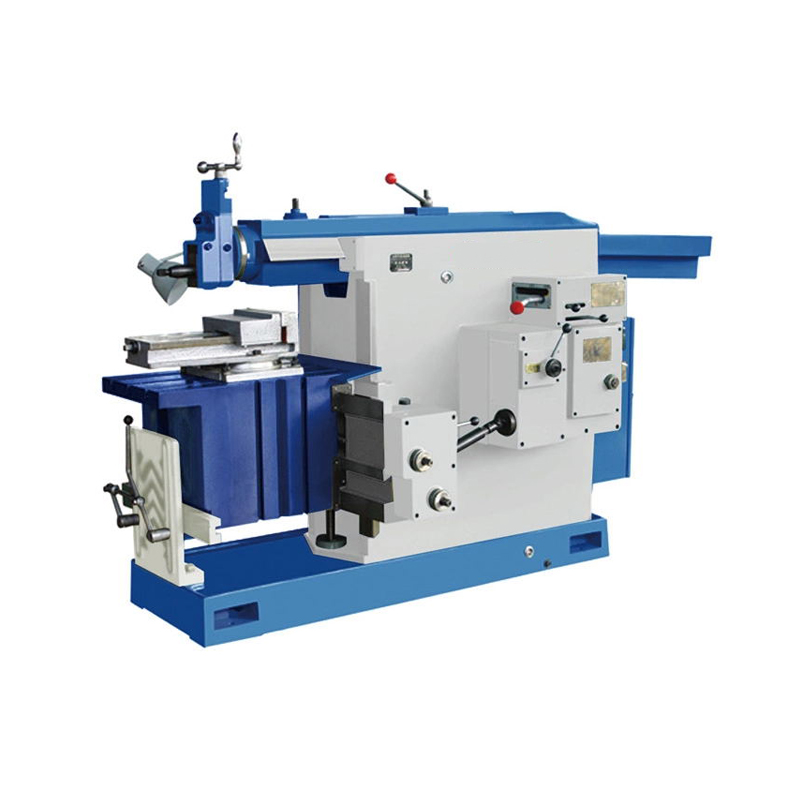

BC6063

BC6063Planing length 630mm

Worktable size 630x400mm

¥0.00 ¥0.00VIP : ¥ -

PM

PMCutter dia. 12-50mm

¥0.00 ¥0.00VIP : ¥ -

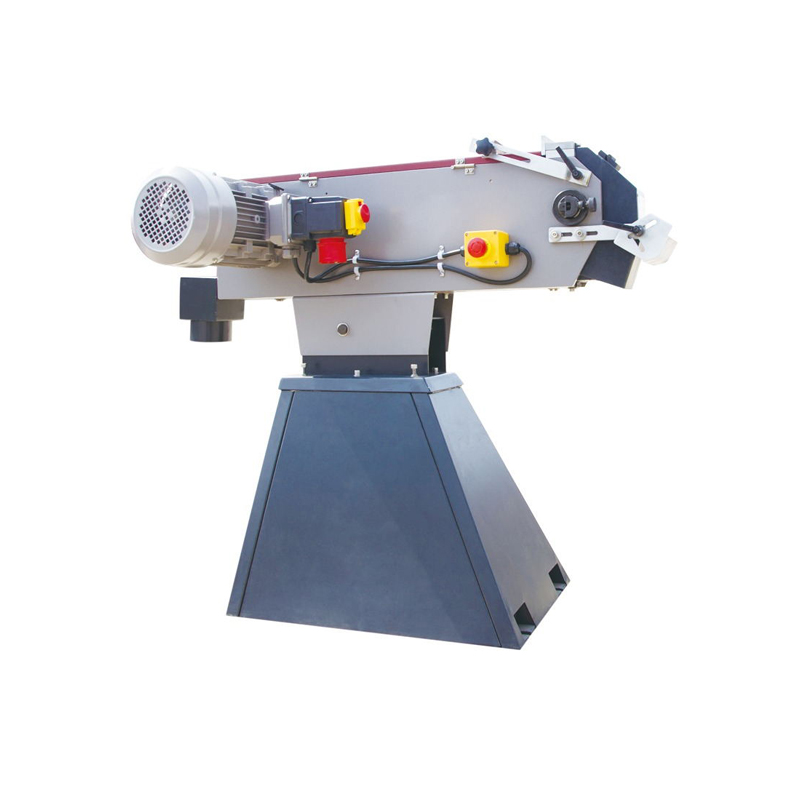

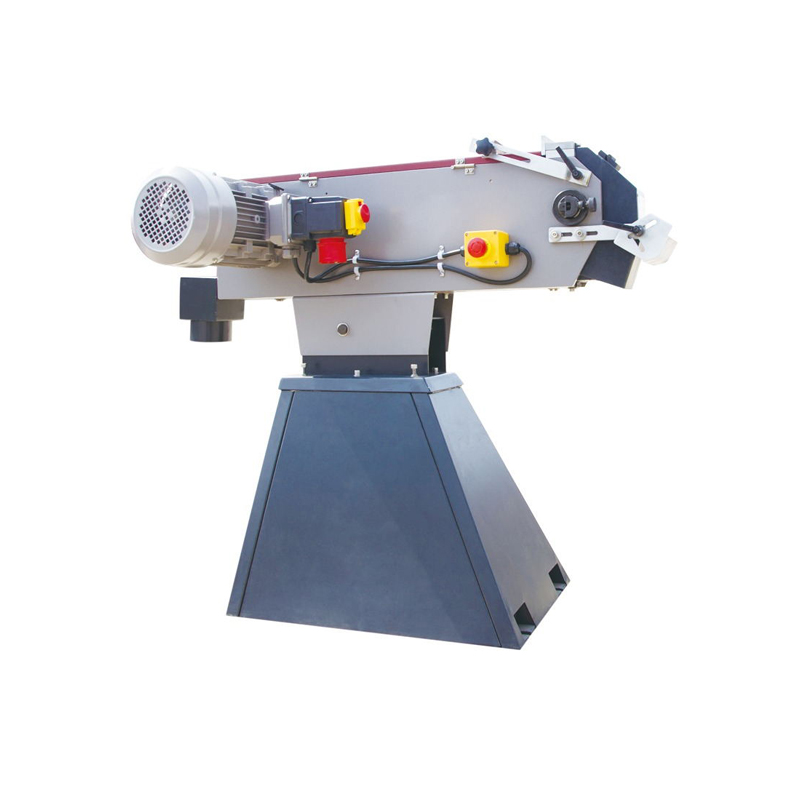

BG-150

BG-150Contact wheel 200x150mm

Face grinding surface 590x150mm

¥0.00 ¥0.00VIP : ¥

What product are you looking for?

Feel free to check our products, it would be our pleasure if some of them happen to be just as you want them to be.

Here We Are

Qingzhou Shengmao Machinery Co., Ltd.

South Hedong Village,

Yidu Subdistrict, Qingzhou City, Shandong Province, China 262500

© 2024 Qingzhou Shengmao Machinery Co., Ltd. All rights reserved