- Home

-

Machines

- Horizontal Lathe

- CNC Flat Bed Lathe

- CNC Slant Bed Lathe

- Vertical Lathe

- Pipe Threading Lathe

- See All Lathe

- Vertical Machining Center

- Milling and Boring Machine

- Conventional Milling Machine

- Drilling and Milling Machine

- See All Milling Machine

- Magnetic Drilling Machine

- Belt-driven Drilling Machine

- Gear-driven Drilling Machine

- Radial Drilling Machine

- See All Drilling Machine

- Belt Disc Grinder

- Bench Grinder

- Tool Grinder

- Surface Grinding Machine

- Cylindrical Grinding Machine

- See All Grinding Machine

-

Accessories

- Tool Holder

- Drill Chuck

- Lathe Center

- Lathe Chuck

- Lathe Toolpost Grinder

- Quick Change Tool Post

- Clamping Kit

- Parallel Tool

- Power Feed

- Dividing Head

- Rotary Table

- Work Table

- Machine Vise

- Slotting Head

- Machine Mount

- Magnetic Tool

- Work Lamp

- Digital Readout

- Coolant and Lubrication

- See All Machine Accessory

- Resources

- Our Company

- Contact Us

- Current location:

- Home

- Machines

- Lathe

- Horizontal Lathe

- CW61100B,CW61125B,CW61140B,CW61160B

CW61100B,CW61125B,CW61140B,CW61160B

Ordinary heavy duty 6T manual machine

This series of machine are mainly used to undertake all kinds of turning work, it can turn all kinds of parts of the end, cylindrical, bore and metric thread, inch thread, modulus thread, diameter thread. Can be used on the turret to cut the taper alone, but also can be used on the knife with the vertical feed with the long taper motor. In addition can also bear the drilling, nesting, boring and other processes. The machine power, rigidity, and can use carbide cutting tools for thread cutting, to process a variety of ferrous metals and non-ferrous metals.

CW61100B is the basic product, the maximum diameter of the bed diameter of 1000mm.

CW61125B is the basic heightening products, the maximum diameter of the body diameter of 1250mm.

CW61140B is the basic heightening of the product, the maximum diameter of the body diameter of 1400mm.

CW61160B is a special high-increase products, the maximum diameter of the body diameter of 1600mm.

Specifications | CW61100B | CW61125B | CW61140B | CW61160B |

CAPACITY | ||||

Swing over bed | 1000mm | 1250mm | 1400mm | 1640mm |

Swing over carriage | 615mm | 865mm | 1015mm | 1250mm |

Max. length of workpiece | 1500 2000 3000 4000 5000 6000 8000 10000 12000mm | |||

Max. turning length | 1300 1800 2800 3800 4800 5800 7800 9800 11800mm | |||

Pan of guideway | 755mm | |||

SPINDLE | ||||

Spindle nose | A2-15 (8xM22) | |||

Spindle bore | 130mm | |||

Taper hole of spindle | 1:20/140mm | |||

Range of spindle speeds | Forward:3.15~315r/min Reverse:3.5~291r/min | |||

No. of spindle speeds | Forward:21 Reverse:12 | |||

FEED | ||||

No. of Longitudinal and cross | 56/56 | |||

Feed per revolution | Longitudinal:0.1~12mm; Cross:0.05~6mm; Top slide:0.025~3mm | |||

No. and range of metric thread | 44; 1~120mm | |||

No. and range of inch thread | 31; 28~1/4" | |||

No. and range of module thread | 45; 0.5~60mm | |||

No. and range of dia. thread | 38; 1/2~56DP | |||

TURRET | ||||

Distance of center line and tool resting plane | 48mm | |||

Tool post swing range | ±90° | |||

Max. travel of cross slide | 520mm | 580mm | 580mm | 630mm |

Max. travel of top slide | 300mm | |||

Section of tool shank | 45mm | |||

Rapid travel speeds | Longitudinal:3740mm/min; Cross:1870mm/min; Little slide:935mm/min | |||

TAILSTOCK | ||||

Dia. of tailstock | 160mm (6″) | |||

Travel of tailstock quill | 300mm (12″) | |||

Taper hole of tailstock quill | MT6 | |||

OTHERS | ||||

Main motor power | 22kW | |||

Length | 4600 5100 6100 7100 8100 9100 11100 13100 15100mm | |||

Width | 2150mm | |||

Height | 1700 1825 2150mm | |||

Max. weight of workpiece | 6000kg | |||

CW61100B/CW61125B/CW61160B horizontal lathe is suitable for machining large and medium-sized parts of castings, steel parts and non-ferrous metals. It can turn external circles, internal holes, end faces, grooving, drilling, boring and nesting, and can turn various internal and external threads in metric, imperial, module and diameter knots, etc. It can be used to turn short conical surfaces with the upper tool holder alone, and can also be used to turn long conical surfaces with the upper tool holder and longitudinal feed. The machine has high power, high rigidity and a wide range of rotational speeds, allowing for high speed and powerful cutting.

Structural features.

1. Highly rigid overall bed

The bed adopts the overall casting structure bed, the internal ribbed plate layout is reasonable, has high rigidity, the guide rail adopts medium frequency quenching and grinding technology. In the sliding guide surface using the anti-crawling guide plate and other technological measures, friction damping coefficient and other dynamic characteristics in the best state, to avoid the occurrence of low-speed crawling phenomenon.

2. High rigidity and high precision spindle

The spindle bearings of the machine are made of products from domestic famous brand enterprises. The spindle box adopts a symmetrical structure, so that the thermal deformation is uniform and the spindle centre is not shifted. In order to reduce thermal deformation, the headstock box adopts oil bath circulation lubrication. The front end of the spindle adopts a three-support structure with bi-directional angular contact ball bearings, which improves the accuracy and enhances the rigidity. The gears in the spindle box are quenched and ground to ensure accurate transmission and low noise. The carefully assembled spindle has the characteristics of low temperature rise, small thermal deformation and high precision, so that the spindle can maintain the relative stability of each precision when working for a long time.

Standard Accessories | Optional Accessories |

4 Jaw chuck Ø1000mm | Special size 4 Jaw chuck |

Steady rest (≥2m length lathe) | MT6 live center |

Follow rest (≥2m length lathe) | Rotary tailstock |

MT6 lathe dead center | Electric tailstock |

Coolant system | Chuck cover |

Working light | Toolpost cover |

Anchor bolts | Chain system |

Manual tailstock |

Recommended Products

-

HP-50S,HP-80S

HP-50S,HP-80SPressure force 50-80t

Table travel 405-450mm

¥0.00 ¥0.00VIP : ¥ -

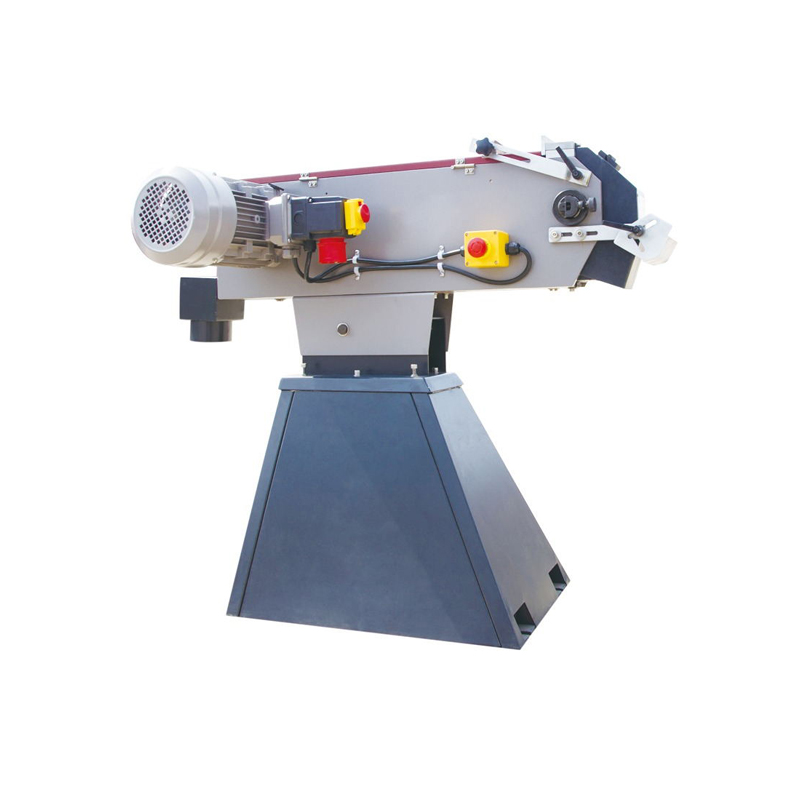

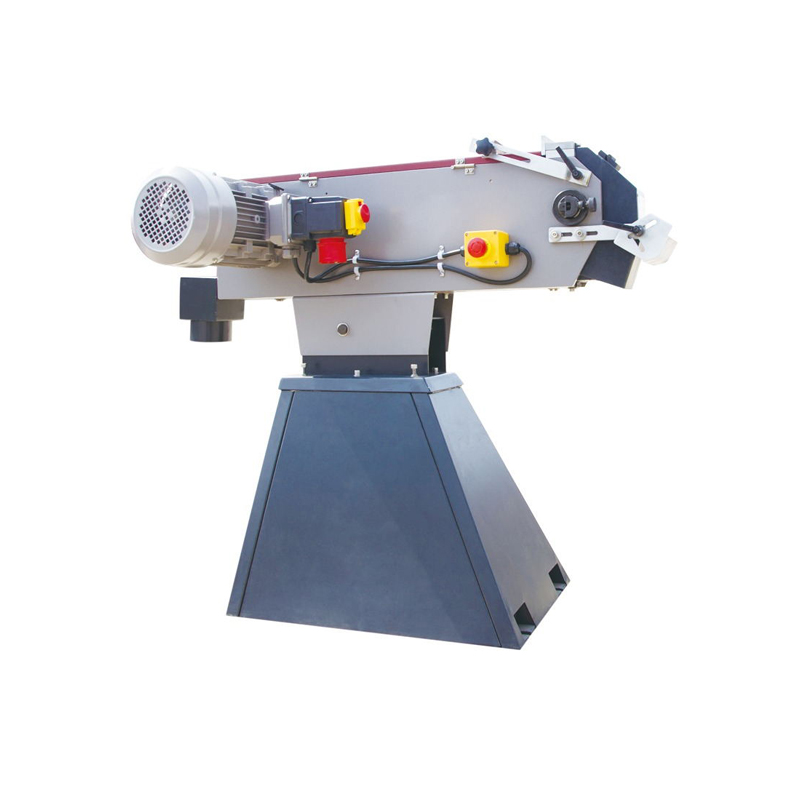

BG-150

BG-150Contact wheel 200x150mm

Face grinding surface 590x150mm

¥0.00 ¥0.00VIP : ¥ -

DDP-0.5,DDP-1,DDP-2,DDP-3

DDP-0.5,DDP-1,DDP-2,DDP-3Pressure force 0.5-3t

¥0.00 ¥0.00VIP : ¥ -

Q1343

Q1343Swing over bed 1000mm

Spindle bore 440mm

¥0.00 ¥0.00VIP : ¥ -

QC12Y

QC12YShear thickness 4-30mm

Shear width 1500-6000mm

¥0.00 ¥0.00VIP : ¥ -

KSE200

KSE200Speed 2950rpm

Motor power 900W

¥0.00 ¥0.00VIP : ¥ -

PS350

PS350Speed 2950rpm

Motor power 900W

¥0.00 ¥0.00VIP : ¥ -

PS200,PS250

PS200,PS250Speed 2950rpm

Motor power 900W

¥0.00 ¥0.00VIP : ¥ -

TX-MD200

TX-MD200Manual chamfer

Bevel angle 15/20/25°

Chamfering range 0-2mm

¥0.00 ¥0.00VIP : ¥ -

3M9735A

3M9735AWorking length 1300-1500mm

Working width 350-400mm

¥0.00 ¥0.00VIP : ¥ -

LDB Live Center

LDB Live CenterMT3-6

Max. speed 4000rpm

¥0.00 ¥0.00VIP : ¥ -

Broach Set

Broach SetMetric & Inch

¥0.00 ¥0.00VIP : ¥ -

X715,X716

X715,X716Table size 2100x500/2500x600mm

Travel X axis 1500/1800mm

¥0.00 ¥0.00VIP : ¥ -

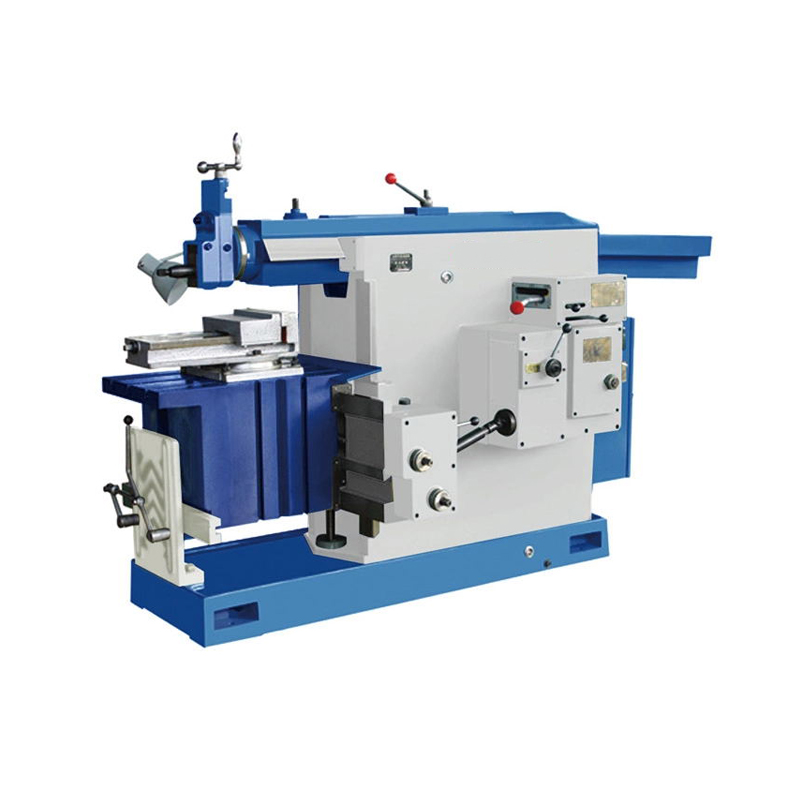

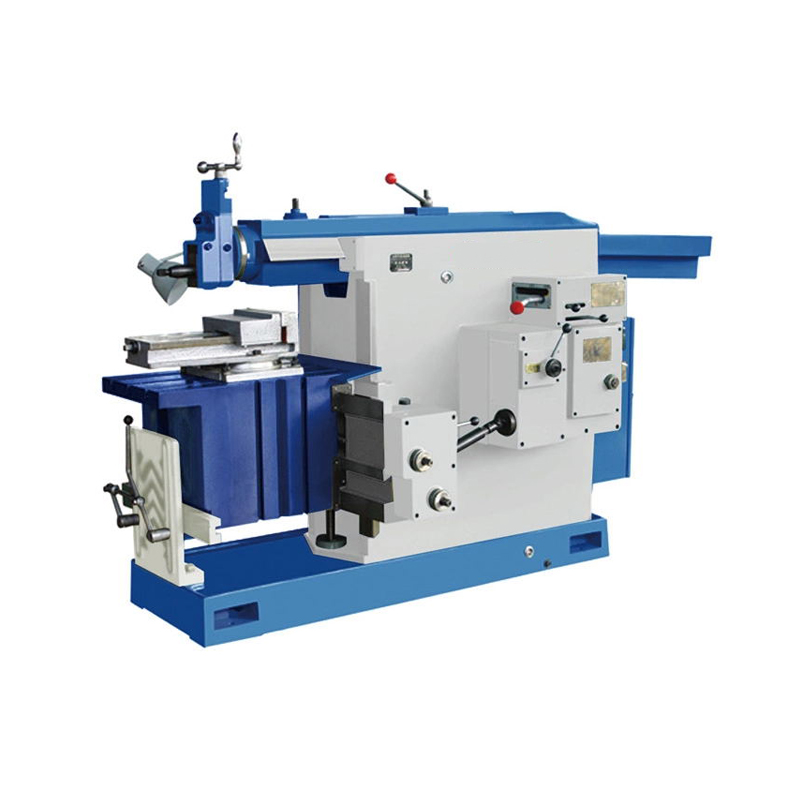

BC6063

BC6063Planing length 630mm

Worktable size 630x400mm

¥0.00 ¥0.00VIP : ¥ -

3M9735B

3M9735BWorking length 1300-1500mm

Working width 350-400mm

¥0.00 ¥0.00VIP : ¥

What product are you looking for?

Feel free to check our products, it would be our pleasure if some of them happen to be just as you want them to be.

Here We Are

Qingzhou Shengmao Machinery Co., Ltd.

South Hedong Village,

Yidu Subdistrict, Qingzhou City, Shandong Province, China 262500

© 2024 Qingzhou Shengmao Machinery Co., Ltd. All rights reserved