- Home

-

Machines

- Horizontal Lathe

- CNC Flat Bed Lathe

- CNC Slant Bed Lathe

- Vertical Lathe

- Pipe Threading Lathe

- See All Lathe

- Vertical Machining Center

- Milling and Boring Machine

- Conventional Milling Machine

- Drilling and Milling Machine

- See All Milling Machine

- Magnetic Drilling Machine

- Belt-driven Drilling Machine

- Gear-driven Drilling Machine

- Radial Drilling Machine

- See All Drilling Machine

- Belt Disc Grinder

- Bench Grinder

- Tool Grinder

- Surface Grinding Machine

- Cylindrical Grinding Machine

- See All Grinding Machine

-

Accessories

- Tool Holder

- Drill Chuck

- Lathe Center

- Lathe Chuck

- Lathe Toolpost Grinder

- Quick Change Tool Post

- Clamping Kit

- Parallel Tool

- Power Feed

- Dividing Head

- Rotary Table

- Work Table

- Machine Vise

- Slotting Head

- Machine Mount

- Magnetic Tool

- Work Lamp

- Digital Readout

- Coolant and Lubrication

- See All Machine Accessory

- Resources

- Our Company

- Contact Us

- Current location:

- Home

- Machines

- Milling Machine

- Vertical Machining Center

- VMC1160

VMC1160

This vertical machining centre is suitable for machining and mould making. It can adapt to machining requirements from roughing to finishing and can complete various processes such as milling, drilling, tapping and boring.

The basic parts are made of high-strength cast iron with aging treatment to ensure the stability of accuracy.

X, Y, Z three direction feed using large-pitch high-precision and high-strength ball screws, high feed speed.

The servo motor is directly connected with the screw by flexible coupling to ensure the positioning accuracy of the machine.

The screw is pre-drawn structure, which greatly reduces the influence of thermal deformation on positioning accuracy.

Specifications | VMC1160 | VMC1275 | VMC1370 | VMC1580 |

Table size | 1200x600mm | 1400x750mm | 1500x700mm | 1600x800mm |

Table travel X/Y/Z | 1100/600/600mm | 1200/750/600mm | 1300/700/700mm | 1500/800/700mm |

Max. table load | 800kg | 1000kg | 1000kg | 1500kg |

T slot (n-w-d) | 5-18-125mm | 7-18-100mm | 7-18-100mm | 5-18-140mm |

Spindle speed range and driving method | 8000rpm belt driving | 8000rpm belt driving | 8000rpm belt driving | 6000rpm belt driving |

Spindle diameter | 150mm | 150mm | 150/155mm | 155/190mm |

Spindle taper | BT40 | BT40 | BT40/BT50 | BT50 |

Distance between spindle and table surface | 120-720mm | 130-830mm | 160-860mm | 155-855mm |

Spindle center to column surface | 650mm | 830mm | 740mm | 855mm |

Rapid feed speed X | 36m/min | 24m/min | 24m/min | 24m/min |

Rapid feed speed Y | 24m/min | 24m/min | 24m/min | 24m/min |

Rapid feed speed Z | 24m/min | 20m/min | 18m/min | 20m/min |

Cutting feed rate | 1-10000mm/min | 1-8000mm/min | 1-8000mm/min | 1-8000mm/min |

Main motor power | 11kW | 11kW | 11/15kW | 15kW |

Magazine capacity | 24t | 24t | 24t | 24t |

Magazine type | Disc type | Disc type | Disc type | Disc type |

Max. tool diameter | Φ75/150mm | Φ80/150, Φ80/130mm | Φ105/200mm | Φ105/200mm |

Max. tool length | 300mm | 300mm | 300mm | 300mm |

Max. tool weight | 6/7kg | 6/7kg | 7kg | 15kg |

Positioning accuracy | ±0.004mm | ±0.005mm | ±0.005mm | ±0.005mm |

Repeatability | ±0.002mm | ±0.003mm | ±0.003mm | ±0.003mm |

Weight | 6600kg | 8500kg | 11500kg | 15000kg |

Overall size | 2900x2400x2800mm | 3500x2700x2700mm | 3800x3200x3000mm | 4000x3400x3100mm |

Standard Accessories | Optional Accessories |

Siemens 828D/FANUC Oi MF | Mitsubishi M80, KND, GSK, SYNTEC, Fagor |

24 tools arm type magazine | Chain-type chip conveyor |

CTS (coolant through spindle) | |

Spindle oil cooling | |

CNC 4th/5th axis |

Recommended Products

-

Z5150A

Z5150ADrilling capacity 50mm

Spindle taper MT5

Table size 560x480mm

¥0.00 ¥0.00VIP : ¥ -

ZS1725F

ZS1725FDrilling diameter 25mm

Tapping M12

Motor power 750W

Table size 320x320mm

Height 1630mm

¥0.00 ¥0.00VIP : ¥ -

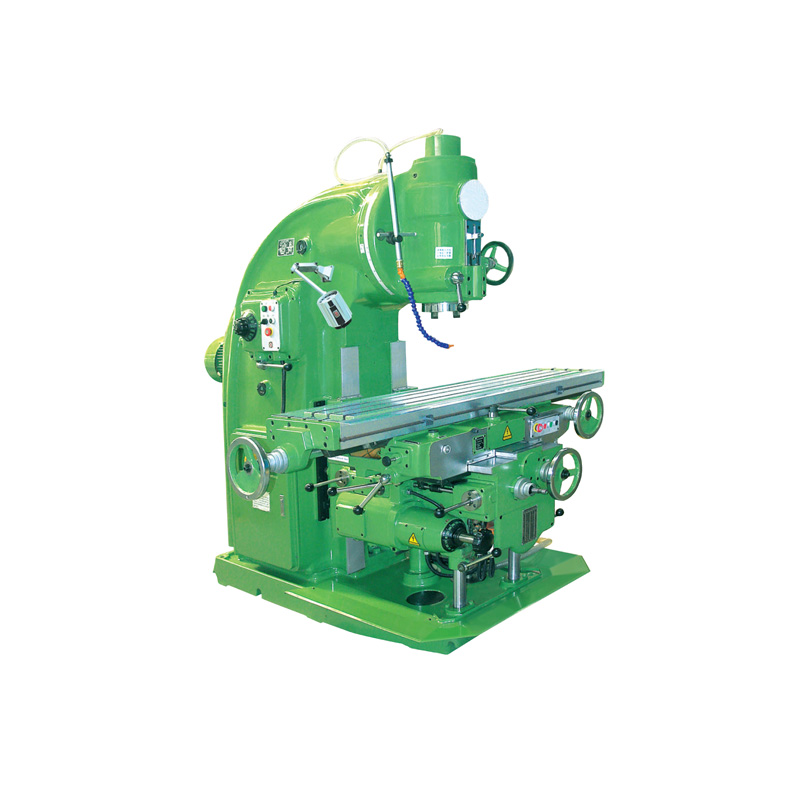

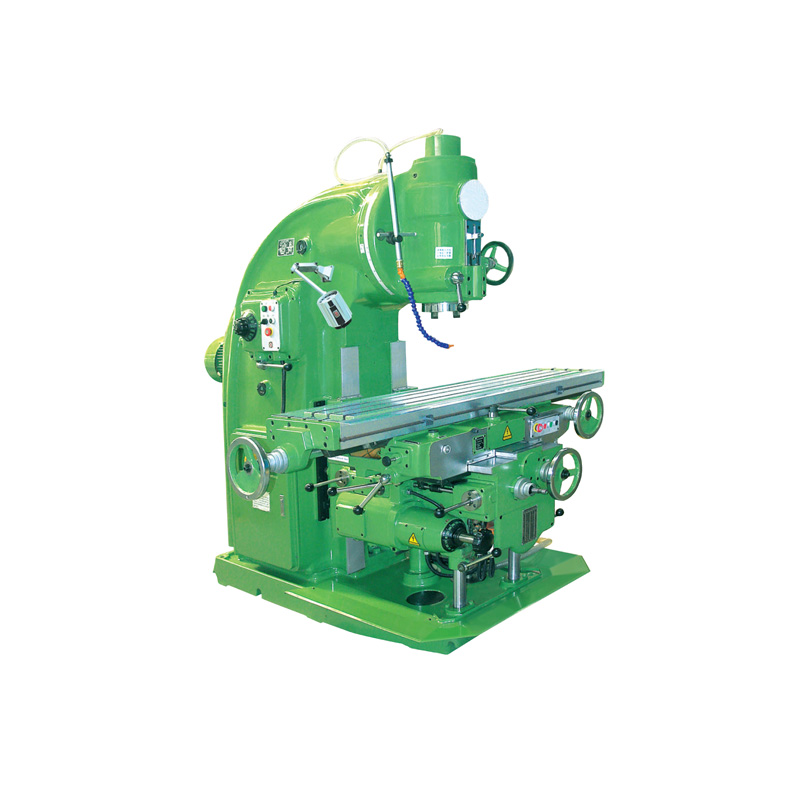

X6325

X6325Table size 1270/1370x254mm

Travel X axis 820/920mm

Spindle taper R8/ISO30/ISO40

Spindle motor 3HP

¥0.00 ¥0.00VIP : ¥ -

DP43016F-PRO

DP43016F-PRODrilling diameter 25mm

Motor power 1100W

Table size 315x315mm

Height 1635mm

¥0.00 ¥0.00VIP : ¥ -

DP51020F-VS

DP51020F-VSDrilling diameter 32mm

Motor power 1500W

Table size 475x425mm

Height 1690mm

¥0.00 ¥0.00VIP : ¥ -

EOC Nut

EOC NutEOC16/25/32

¥0.00 ¥0.00VIP : ¥ -

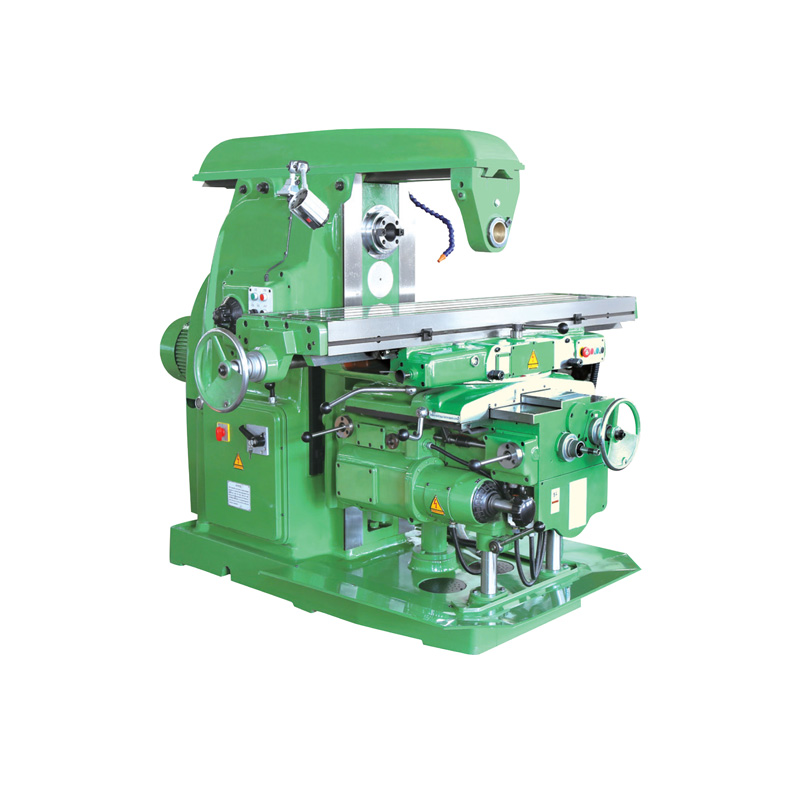

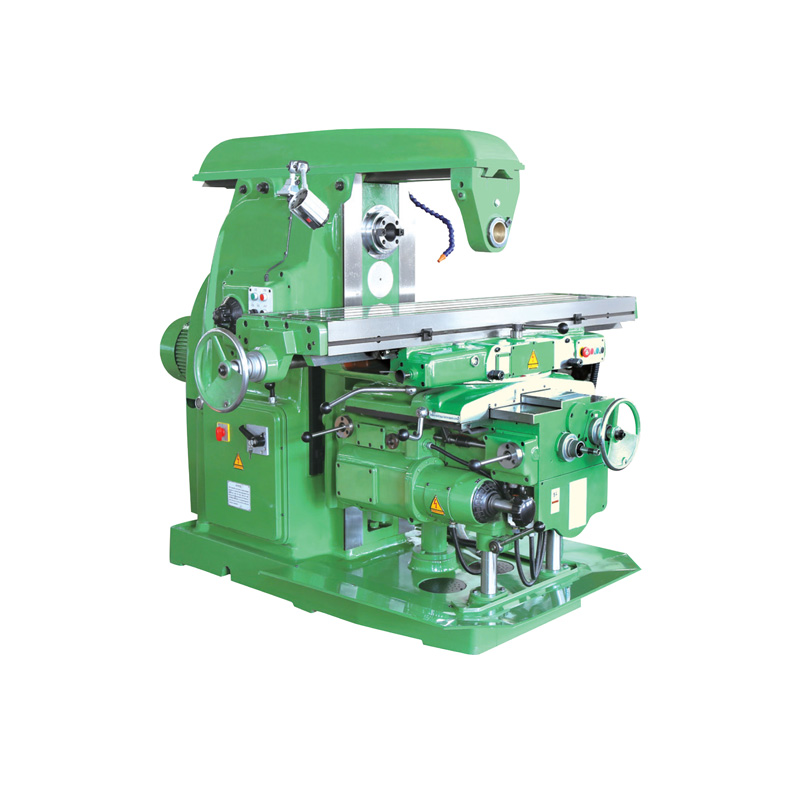

X6132

X6132Table size 1325x320mm

Travel X axis 700mm

¥0.00 ¥0.00VIP : ¥ -

SK Spanner

SK SpannerSK6-25

¥0.00 ¥0.00VIP : ¥ -

XL6436C,XL6436CL

XL6436C,XL6436CLTable size 1325/1600x360mm

Travel X axis 1100/1300mm

¥0.00 ¥0.00VIP : ¥ -

X5040

X5040Table size 1700x400mm

Travel X axis 900mm

¥0.00 ¥0.00VIP : ¥ -

X6140

X6140Table size 1700x400mm

Travel X axis 900mm

¥0.00 ¥0.00VIP : ¥ -

XL6230

XL6230Table size 1270x300mm

Travel X axis 720mm

¥0.00 ¥0.00VIP : ¥ -

XL8132,XL8140,XL8145

XL8132,XL8140,XL8145Horizontal table size 750x320mm

Vertical table size 890x225mm

Travel X/Y/Z 405/305/400mm

¥0.00 ¥0.00VIP : ¥ -

XL6036C

XL6036CTable size 1325x360mm

Travel X axis 1100mm

¥0.00 ¥0.00VIP : ¥ -

WM210V-G

WM210V-GSwing over bed 210mm

Workpiece length 400mm

Spindle bore 21mm

Spindle speed 50-2500rpm

¥0.00 ¥0.00VIP : ¥

What product are you looking for?

Feel free to check our products, it would be our pleasure if some of them happen to be just as you want them to be.

Here We Are

Qingzhou Shengmao Machinery Co., Ltd.

South Hedong Village,

Yidu Subdistrict, Qingzhou City, Shandong Province, China 262500

© 2024 Qingzhou Shengmao Machinery Co., Ltd. All rights reserved