- Home

-

Machines

- Horizontal Lathe

- CNC Flat Bed Lathe

- CNC Slant Bed Lathe

- Vertical Lathe

- Pipe Threading Lathe

- See All Lathe

- Vertical Machining Center

- Milling and Boring Machine

- Conventional Milling Machine

- Drilling and Milling Machine

- See All Milling Machine

- Magnetic Drilling Machine

- Belt-driven Drilling Machine

- Gear-driven Drilling Machine

- Radial Drilling Machine

- See All Drilling Machine

- Belt Disc Grinder

- Bench Grinder

- Tool Grinder

- Surface Grinding Machine

- Cylindrical Grinding Machine

- See All Grinding Machine

-

Accessories

- Tool Holder

- Drill Chuck

- Lathe Center

- Lathe Chuck

- Lathe Toolpost Grinder

- Quick Change Tool Post

- Clamping Kit

- Parallel Tool

- Power Feed

- Dividing Head

- Rotary Table

- Work Table

- Machine Vise

- Slotting Head

- Machine Mount

- Magnetic Tool

- Work Lamp

- Digital Readout

- Coolant and Lubrication

- See All Machine Accessory

- Resources

- Our Company

- Contact Us

- Current location:

- Home

- Machines

- Lathe

- Pipe Threading Lathe

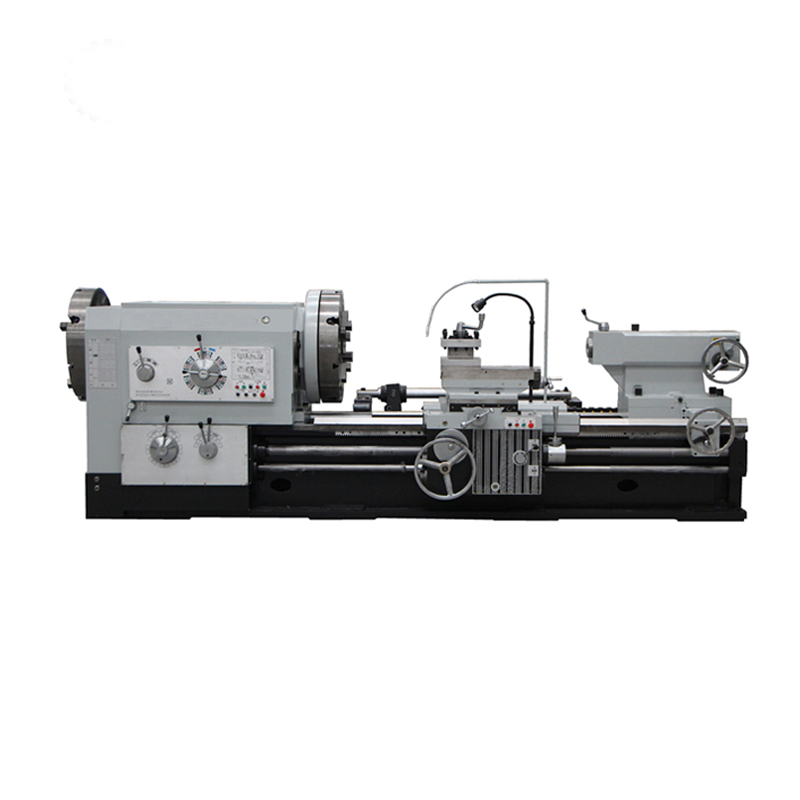

- Q1325C,Q1327C

Q1325C,Q1327C

Q13 series pipe threading lathe mainly used for turning the internal and external threads including metric and inch thread, as well as having all the common functions of normal engine lathe such as processing the inner bore, end face of shafts and disks, this series is equipped with taper guide bar device which enables this series to process taper thread, this series is widely used in industries including petroleum exploiting, minerals mining, chemical piping and geological prospecting, for processing and repairing drilling pipe, drilling rod, thread coupling and so on.

Big spindle bore and double chuck allows clamp and process big diameter pipes

Integral machine bed adopts high strength iron to realize high rigidity and precision

Ultrasonic frequency quenched guide-ways are hard enough for good wear-resistance

Equipped with taper guide bar device this enables the machine to process taper threads

Specification | Unit | Q1325C | Q1327C |

Capacity | |||

Max. swing over bed | mm | 800 | 800 |

Max. swing over cross slide | mm | 480 | 480 |

Distance between centers | mm | 1500/3000 | 1500/3000 |

Pipe threading range | mm | 50-250 | 50-270 |

Bed width | mm | 600 | 600 |

Max. load capacity | t | 4 | 4 |

Spindle | |||

Spindle bore | mm | 255 | 280 |

Spindle speed steps | steps | VF 4 steps | VF 4 steps |

Spindle speed | rpm | 20-420 | 20-420 |

Chuck size (manual) | mm | 630 4-jaw | 630 4-jaw |

Turret | |||

Turret/toolpost (electric) | - | 4 | 4 |

Tool shank size | mm | 32x32 | 32x32 |

Feed | |||

X-axis travel | mm | 420 | 420 |

Z-axis travel | mm | 1250/2750 | 1250/2750 |

X-axis feed range (steps) | mm/r | 22/ 0.02-0.45 | 22/ 0.02-0.45 |

Z-axis feed range (steps) | mm/r | 26/ 0.07-1.33 | 26/ 0.07-1.33 |

X-axis rapid feed speed | mm/min | 2300 | 2300 |

Z-axis rapid feed speed | mm/min | 4000 | 4000 |

No. of Metric thread and range | mm | 24/ 1-15 | 24/ 1-15 |

No. of Inch thread and range | TPI | 40/ 14-1 | 40/ 14-1 |

Tailstock | |||

Tailstock quill diameter | mm | 120 | 120 |

Tailstock quill taper | - | MT6 | MT6 |

Tailstock quill travel | mm | 250 | 250 |

Others | |||

Main motor power | kW | 15 | 15 |

Rapid feed motor power | kW | 1.1 | 1.1 |

Coolant motor power | kW | 0.125 | 0.125 |

Machine dimensions (LxWxH) | mm | 4100/5600x1700x1600 | 4100/5600x1700x1600 |

Machine weight | kg | 8000/9000 | 8000/9000 |

Standard Accessories | Optional Accessories |

4 jaw manual chuck | 2 or 3 axis digital indicator |

Steady rest | Chuck guard |

Follow rest | Tool-post guard |

Dead center of tailstock | Rear splash guard |

4 station tool post | Quick change tool post |

Taper turning attachment | Rear support for long pipe |

Cooling system | Live center |

Work lamp | |

Chip plate | |

Tools | |

Leveling wedge and bolts | |

Operation manual (English) |

Recommended Products

-

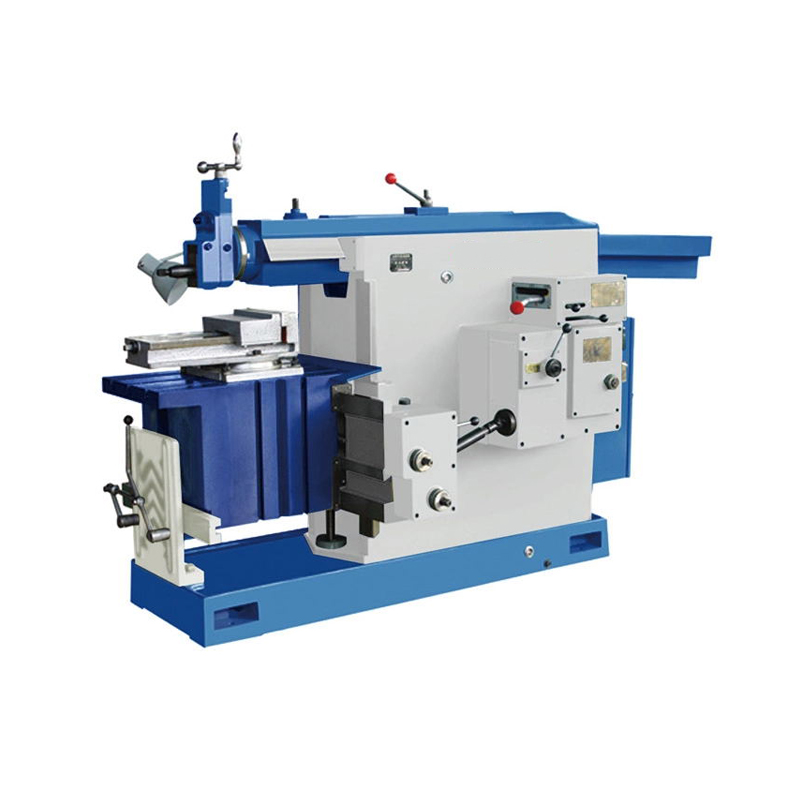

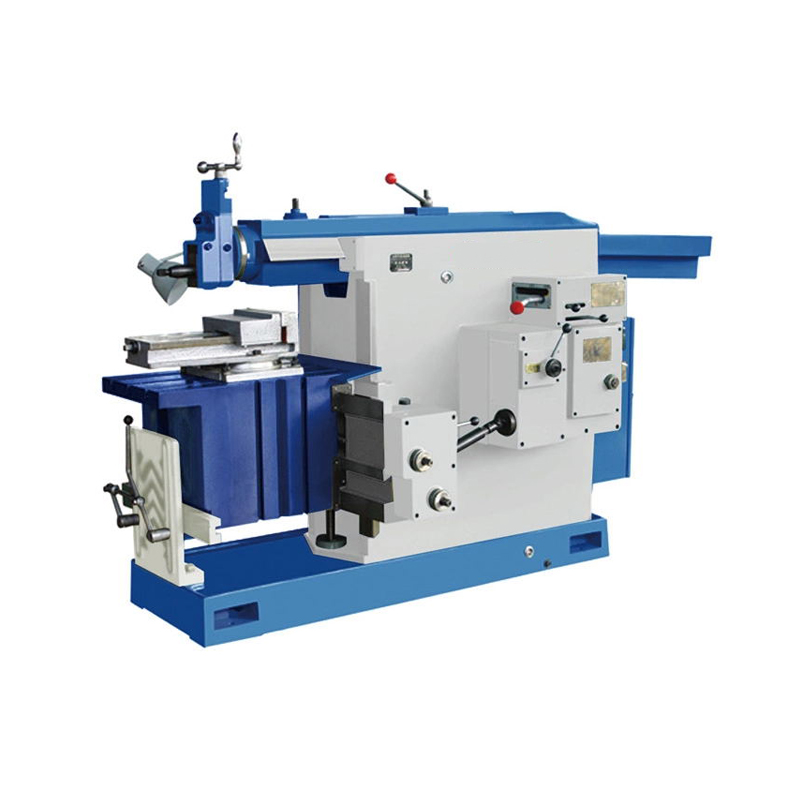

BC6063

BC6063Planing length 630mm

Worktable size 630x400mm

¥0.00 ¥0.00VIP : ¥ -

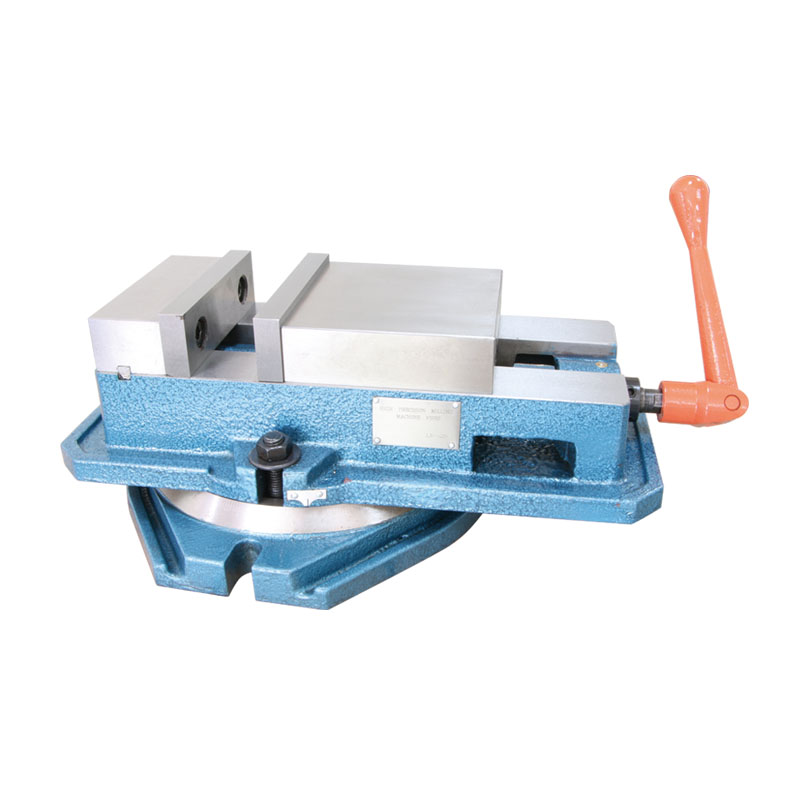

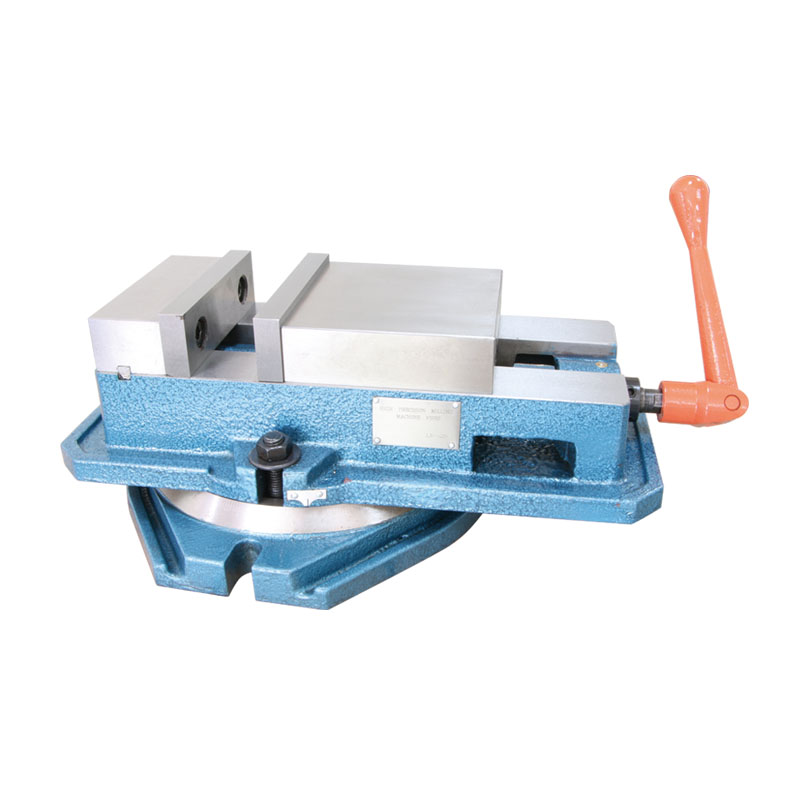

LV-75

LV-75Jaw opening 75-218mm

¥0.00 ¥0.00VIP : ¥ -

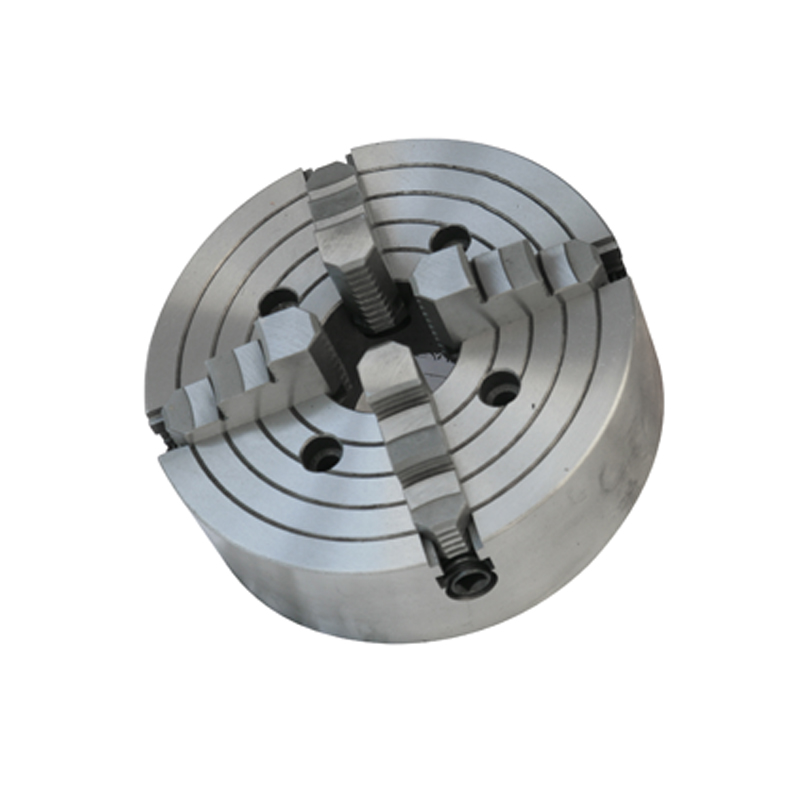

CK

CKM6-30

¥0.00 ¥0.00VIP : ¥ -

S0,S1,S1X,S2,S2T,S3,S3X,S4

S0,S1,S1X,S2,S2T,S3,S3X,S4Lathe swing 228-762mm

¥0.00 ¥0.00VIP : ¥ -

M,AR-AP,A,BR-BP,B,C,D

M,AR-AP,A,BR-BP,B,C,DLathe swing 180-1200mm

¥0.00 ¥0.00VIP : ¥ -

XH716D,XH717D

XH716D,XH717DTravel X/Y/Z axis 1200/650/650mm

Worktable size 1400x600mm

¥0.00 ¥0.00VIP : ¥ -

251-100,251-111,251-200,251-222,251-300,251-333,251-400,251-444,251-555

251-100,251-111,251-200,251-222,251-300,251-333,251-400,251-444,251-555Lathe swing 12"-48"

¥0.00 ¥0.00VIP : ¥ -

TOOA0,TOOA1,TOOE5,TOOB2,TOOC3,TOOD1,TOOD2

TOOA0,TOOA1,TOOE5,TOOB2,TOOC3,TOOD1,TOOD2Lathe swing 120-1500mm

¥0.00 ¥0.00VIP : ¥ -

TK22A Front Mount

TK22A Front Mount4 Jaw self centring chuck with 2-piece jaw front mount

¥0.00 ¥0.00VIP : ¥ -

TK22 Front Mount

TK22 Front Mount4 Jaw self centring chuck with solid jaw front mount

¥0.00 ¥0.00VIP : ¥ -

TK21A Front Mount

TK21A Front Mount3 Jaw self centring chuck with 2-piece jaw front mount

¥0.00 ¥0.00VIP : ¥ -

TK21 Front Mount

TK21 Front Mount3 Jaw self centring chuck with solid jaw front mount

¥0.00 ¥0.00VIP : ¥ -

K72 Direct Mount

K72 Direct Mount4 Jaw independent chuck with solid jaw direct mount

¥0.00 ¥0.00VIP : ¥ -

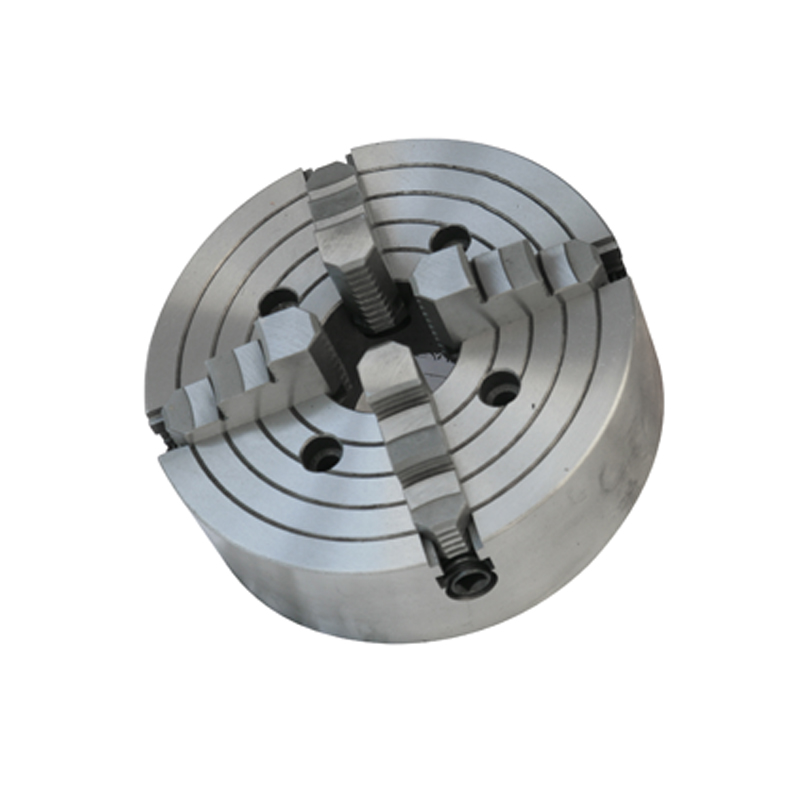

K72

K724 Jaw independent chuck with solid jaw

¥0.00 ¥0.00VIP : ¥ -

SER

SER1Pc

¥0.00 ¥0.00VIP : ¥

What product are you looking for?

Feel free to check our products, it would be our pleasure if some of them happen to be just as you want them to be.

Here We Are

Qingzhou Shengmao Machinery Co., Ltd.

South Hedong Village,

Yidu Subdistrict, Qingzhou City, Shandong Province, China 262500

© 2024 Qingzhou Shengmao Machinery Co., Ltd. All rights reserved